Food Server v2.0

The Food Server v2.0 is the Yogi to the Personal Food Computer’s Boo-Boo. Based at the MIT Bates Linear Particle Accelerator Research Center, my team and I are transforming four shipping containers into indoor farms. The infrastructure we've designed allows for precise control over a plant’s environment, including variables like air temperature, humidity, light spectrum, photoperiod, and root nutrients. Food Server also collects data on its incubated plants and environments. My team was using this agriculture lab to correlate plant characteristics like flavor and rate of growth to the environments from which they were grown and expressed.

As part of our mechatronics team, I helped design and build out Food Server's mechanical components and infrastructure, including LED lighting, water distribution, and HVAC infrastructure.

Hydroponics Design & Production

I designed and built the Food Server’s hydroponic systems, now found in all of our active units in Boston and India. I iterated through the design enough times to have officially patched all of its leaks. Once requiring two dozen components and a near-Home Depot aisle’s worth of tools to assemble, the rack is now built from a simple bill of materials and requires no hand tooling to assemble. It has a bunch of features I like:

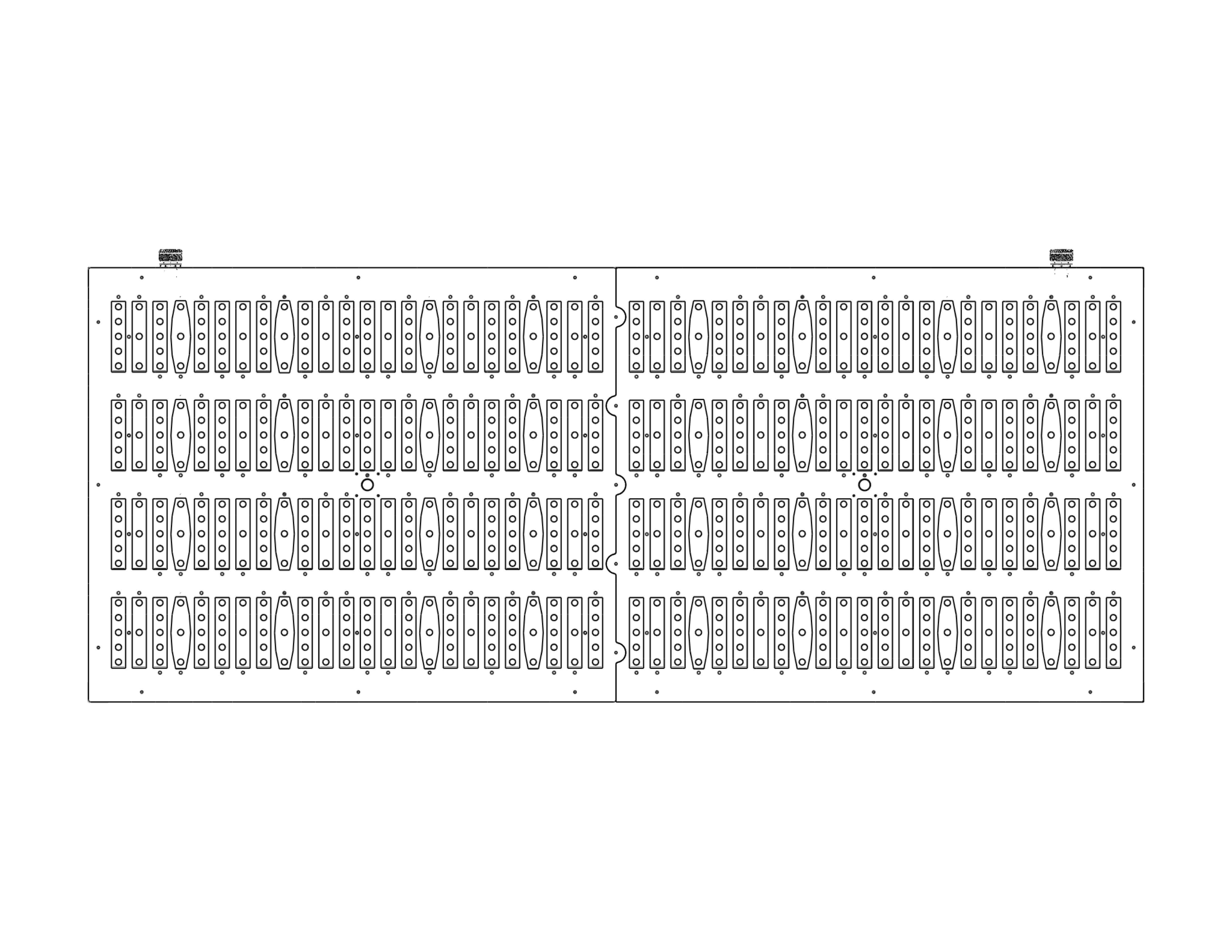

● Vertical space — Up to 150 plants can be grown in one rack. Each rack houses up to three vertical layers, allowing for 24 sq-ft of growing capacity in an 8 sq-ft footprint.

● Waterbot connectivity — The rack plugs into our automated fertigation system, WaterBot. Waterbot delivers programmed nutrient, pH, and stress inducing fluids to each rack in Food Sever. The feature enables the team to run an array of unique root water environments in one Food Server.

● Multi-purpose — Racks can change modes from shallow water culture, deep water culture, nutrient film channel, or aeroponic propagation.

● Mobility and modularity — 12 racks fit inside of Food Server, leaving a middle corrider down its center for researchers and engineers to work and swap them out.

LED Lighting System

One of Food Server’s main points of environmental control is its lighting system. I desigend the Food Server’s LED lighting system under a set of electrical, mechanical, and biological design constraints. The panel’s form factor, power consumption, spectral output, and heat emission properties guided my final design.

I also led the panel's production from prototype to a manufacturing run of 60 units. Intern Alex Flamm from Cornell University, pictured above, assisted me with assembly. Aren’t interns the best? After prototyping in-house, I coordinated contracting out of house for the final production run.

I’m now onto creating a custom chip on board (COB) lighting system for the Tree Computer project. Check out updates on my Tree Computer page as it progresses.

Infrastructure Installation

As engineering tends to go, these new lights created complexity in our HVAC system. Adding light into the box implictly added heat, which our biology team—and plants—didn’t want. Extra heat? No sweat. Our team opted to hack the Triton shipping container’s HVAC system to reroute its airflow, and exhaust its high temperatures. The end result is an homogenous atmospheric environment across all points inside of the chamber. Our design reduced the floor-to-ceiling temperature delta from 12C to under 1C. We then had much more precise control of Food Server’s air temperature and humidity to match the control of its LED’s.

Spilling and water overflow was an issue while I was running Food Server v1.0 at the Media Lab. The mechatronics team and I made the floor of Food Server 2.0 a drain itself, so spills can't occurr while you're inside of it.

Iteration

Food Server v2.0 is an evolution of v1.0, formerly located at the Media Lab. After I oversaw the system in 2016, I learned from its original design—things I liked, things I didn't like. Our v2.0 array underwent many updates in its mechanical design, automation, and sensor integration. Pictured above, a shot I took of v1.0 with Tom in 2015.

Research

After building out hardware and infrastructure components, I oversaw my team's biology experimentation and horticulture inside of the container labs from 2016-2017. For the work I raised hundreds of plants, among a few dozen species, from seed to harvest, to sample vial. Using the tool has been (almost) as fun as building it.