Cotton Computer

My team at MIT Media Lab used its Food Server v2.0 shipping container farm to research cotton production. We worked textile manufacturer, Welspun, to develop indoor propagation techniques, like hydroponics and aeroponics, and to better understand cotton’s ideal growing environments. I led experimental design and propagation at our Food Server facility in Boston in 2017 and 2018. I helped build out a mirror copy of our shipping container system at the Welspun manufacturing center in Anjar, India during summer 2018.

Cotton Propagation

During my previous station at Harvard, I raised 35 local woody plant species in closed environment growth chambers, testing their “budburst” response to an array of spring temperature and light treatments. Raising cotton in Food Server v2.0 is an extension of this work, being a woody species itself. Here the environmental treatments are comprised of high and low nutrient concentrations in the root zone, and plant individuals represent two sets of genetics.

I led the six month grow of 36 cotton plants from seed to harvest in the Boston Food Server v2.0 (above), collecting similar datasets on plant phenology and morphology (e.g. timing of flower production), and plant height. I also designed and built the infrastructure systems in which the plants were propagated, including LED lighting and modular hydroponic systems. More info on those can be found on my Food Server v2.0 page.

Plant Expression for Human Expression

The harvested product is also set to be turned into a denim piece by an undisclosed fashion designer and Media Lab collaborator. The designer uses sustainable materials for their fashion pieces. It’s a fun collab, and I see it as another extension of what motivitates my work at the Media Lab. In building a tool for knowledge forwarding in the field of plant science, my team created a product for human expression.

India Deployment

In 2018 I worked with my lean mechatronics team to build a mirror copy of the Food Server v2.0 in Anjar, India. The platform provides our sponsor company, Welspun, with an on-site laboratory for running horticultural experiments in parallel with the team in Boston. The build-out was both a challenge and a thrill. Before the trip, I procured our full bill of materials, a list comprised of hundreds of components for infrastructure installs ranging from custom HVAC, LED lighting, and irrigation systems. And we were building in rural India, so forgetting any components wasn’t an option. It felt like we were packing for space.

The team executed. Alongside Welspun mechatronics engineers, and now new friends, we built the Food Server v2.0 in one week. The seedlings we planted before departing are alive and well, and should be blooming flowers any day now, according to our remote cameras.

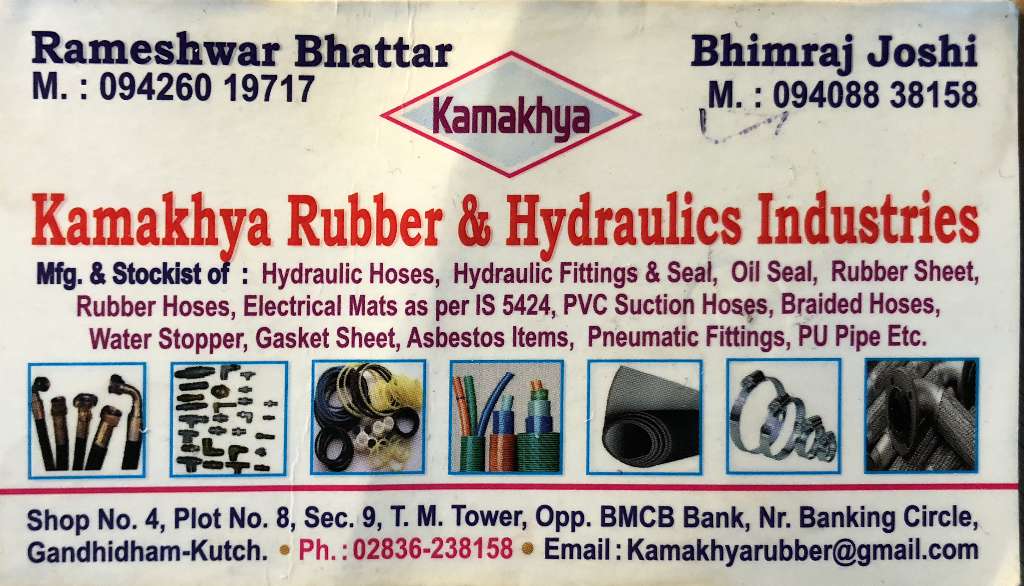

The Elusive Hose Adapter

The most trying moment of the trip occurred when I realized I’d forgotten a pack of ¾” NPT threaded hose adapters. The component was the size of my thumb, but our automated irrigation system depended on it to work, and McMaster Carr doesn’t exactly deliver to Anjar, India. I took a trip into town, to a see a guy—The Guy—who I was told would be the one, if any, who might sell the coveted brass fitting. His name was Rameshwar. I arrived to his shop via taxi. We shook hands. He served me a cardamom tea, with salt to taste. I sketched the part on a piece of paper sitting across from him at his desk. Mechanical engineering was our shared language. Before I finished the drawing, he said, “Come with me.” Rameshwar led me through an Employees Only type of door toward the inventory side of his shop. He looked for no longer than five seconds at a garage door-sized wall of small unlabelled green boxes, and then pulled one out with his index finger. “This is what you’re looking for.” It was the adapter. I headed back to make our WaterBot irrigation line work with the push of a button. McMaster Carr, eat your heart out.